[ad_1]

The BMW Group announced two significant EV-related investments in South Carolina, valued at $1.7 billion in total.

The first part of $1 billion is to prepare for the production of all-electric vehicles at the company’s existing manufacturing facility in South Carolina – Plant Spartanburg.

This 30-year-old site currently produces 11 models including five X-series (X3, X4, X5, X6 and X7), four BMW M models and two plug-in hybrid X models (BMW X3 xDrive30e and BMW X5 xDrive45e, including battery pack assembly). Soon, an all-new hybrid-electric BMW XM will join the lineup. The plant capacity is up to 450,000 vehicles annually and so far, more than 6 million units have been built. Nearly 70,000 “electrified” BMWs were built at the site in 2021 alone.

According to the plan, Plant Spartanburg is expected to produce at least six all-electric BMW X models by 2030. This suggests that basically all models will get more or less direct fully-electric counterparts.

To support local BEV production, the company will invest an additional $700 million in a New High-Voltage Battery Assembly Facility in Woodruff, South Carolina. This new plant will produce battery packs for the all-electric BMW X models.

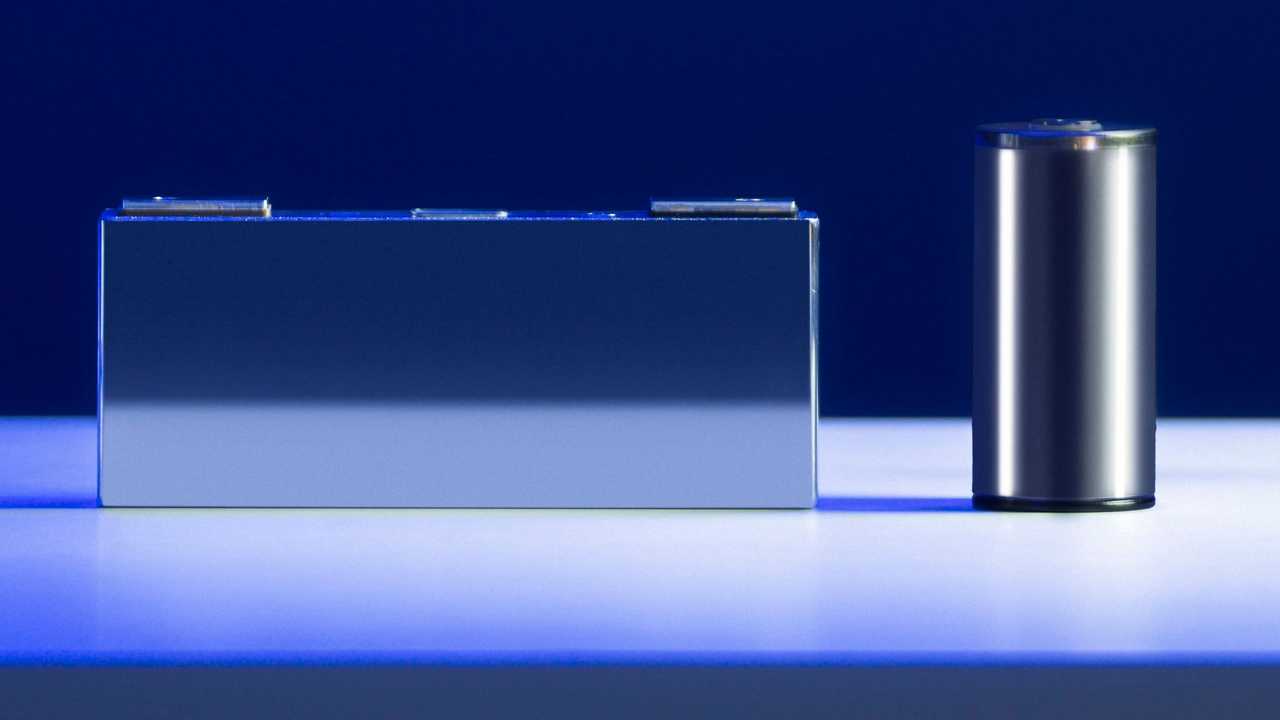

One of the most important parts of the announcement is that the battery packs will be built using BMW’s sixth-generation battery cells, which are cylindrical – a standard diameter of 46 mm and two different heights: 95 and 120 mm.

BMW round battery cell (right) side-by-side- with a prismatic battery cell (left)

BMW Group Chairman of the Board of Management, Oliver Zipse said:

“For decades, Plant Spartanburg has been a cornerstone of the global success of the BMW Group. It is he home of the BMW X models that are so popular all over the world. Going forward, it will also be a major driver for our electrification strategy, and we will produce at least six fully electric BMW X models here by 2030. That means: The ‘Home of the X’ is also becoming the ‘Home of the Battery Electric Vehicle’.

In addition, we can showcase BMW Group’s ‘local for local’ principle: Our newly developed sixth generation battery cells, which were specifically designed for the next generation electric vehicles, will be sourced here in South Carolina – where X goes electric.”

BMW Group investments in South Carolina:

- existing Plant Spartanburg – $1 billion

at least six full-electric BMW X models by 2030 - New High-Voltage Battery Assembly Facility – $700 million

location: in Woodruff, South Carolina (near Plant Spartanburg)

battery pack production using BMW’s sixth generation battery cells

over 1 million sq. ft.

300 new jobs

Another big announcement is that the BMW Group has selected Envision AESC as its lithium-ion battery cell supplier for Plant Spartanburg.

Under the partnership, Envision AESC will build a new battery gigafactory in South Carolina with an output of up to 30 GWh annually (an equivalent of 300,000 vehicles with a 100 kWh battery pack each).

That’s pretty much a hat trick for South Carolina, which attracted three substantial EV-related investments at one time.

It means also that Envision AESC joins CATL and EVE Energy as the third supplier of newly developed round lithium-ion battery cells for the BMW Group.

Let’s recall that the German company intends to have six plants (20 GWh each), including two in Europe, two in China, and two in the North America free trade zone. CATL will build one in China and one in Europe. Same as EVE Energy. With the fifth plant built by Envision AESC (30 GWh instead of 20 GWh), there is just one slot left now for North America.

“In line with the principle of “local for local,” the BMW Group aims to purchase battery cells for its electric vehicles where production takes place. The company has found a partner in Envision AESC, which will build a new battery cell factory in South Carolina, to supply Plant Spartanburg. Envision will produce newly developed round lithium-ion battery cells, which were specifically designed for the sixth generation of BMW eDrive technology and will be used in the next generation electric vehicles.”

Envision AESC gigafactory in South Carolina:

- location: N/A, South Carolina

- value: N/A

- production: potentially from 2026 (according to Envision Group via CnEVPost)

- manufacturing capacity: 30 GWh per year

- batteries: cells BMW’s sixth generation cylindrical battery cells (no info about version – 4695, 46120 or both).

Envision AESC was acquired by Envision Group a few years ago from Nissan, which still holds about a fifth of its former joint venture (originally established with NEC).

The company has a small battery plant in Tennessee and a new battery gigafactory underway in Kentucky. Other Envision AESC facilities are in Japan, China and Europe (UK).

[ad_2]

Source link